Product Description

- Specifications

- Product Options

- Tech Tips

- Announcements

- Documents

Product specifications for BXS6400CM-100FR

The BXS6400CM-100FR specifies: This product has been discontinued, please contact your local sales office for more information.

| Motor Type | - Brushless DC Motor |

| Motor Frame Size | - 4.09 in., 104 mm |

| Output Power | - 400 W (1/2 HP) |

| Power Supply | - Single-Phase, Three-Phase 200-240 VAC |

| Frequency | - 50 Hz, 60 Hz |

| Rated Input Current | - 4.7 A (Single-Phase) 2.8 A (Three-Phase) |

| Shaft/Gear Type | - Hollow Shaft Flat Gearhead |

| Gear Ratio (X:1) | - 100 :1 |

| Output Shaft Diameter | - 25 mm |

| Rated Torque | - 970 lb-in, 110 N·m |

| Electromagnetic Brake | - Equipped |

| Brake Type | - Power off activated type, automatically controller by the driver |

| Static Friction Torque | - 184 oz-in, 1.30 N·m |

| Variable Speed Range (r/min) | - Digital setting: 0.02 ~ 40 r/min (2000:1) Analog setting: 0.3 ~ 40 r/min (133:1) |

| Permissible Load Inertia | - 98000 oz-in², *When instantaneous stop or instantaneous bi-directional operation is performed = 27000 oz-in², 18000 x 10-4 kg·m², *When instantaneous stop or instantaneous bi-directional operation is performed = 5000 x 10-4 kg·m² |

| Permissible Overhung Load | - 0.39 in. from Shaft End = 450 0.79 in. from Shaft End = 400 lb, 10 mm from Shaft End = 2040 20 mm from Shaft End = 1780 N |

| Permissible Thrust Load | - 180 lb, 800 N |

| Max. Extension Length (m) | - Motor and driver distance: 99.7 ft. (30.4 m) |

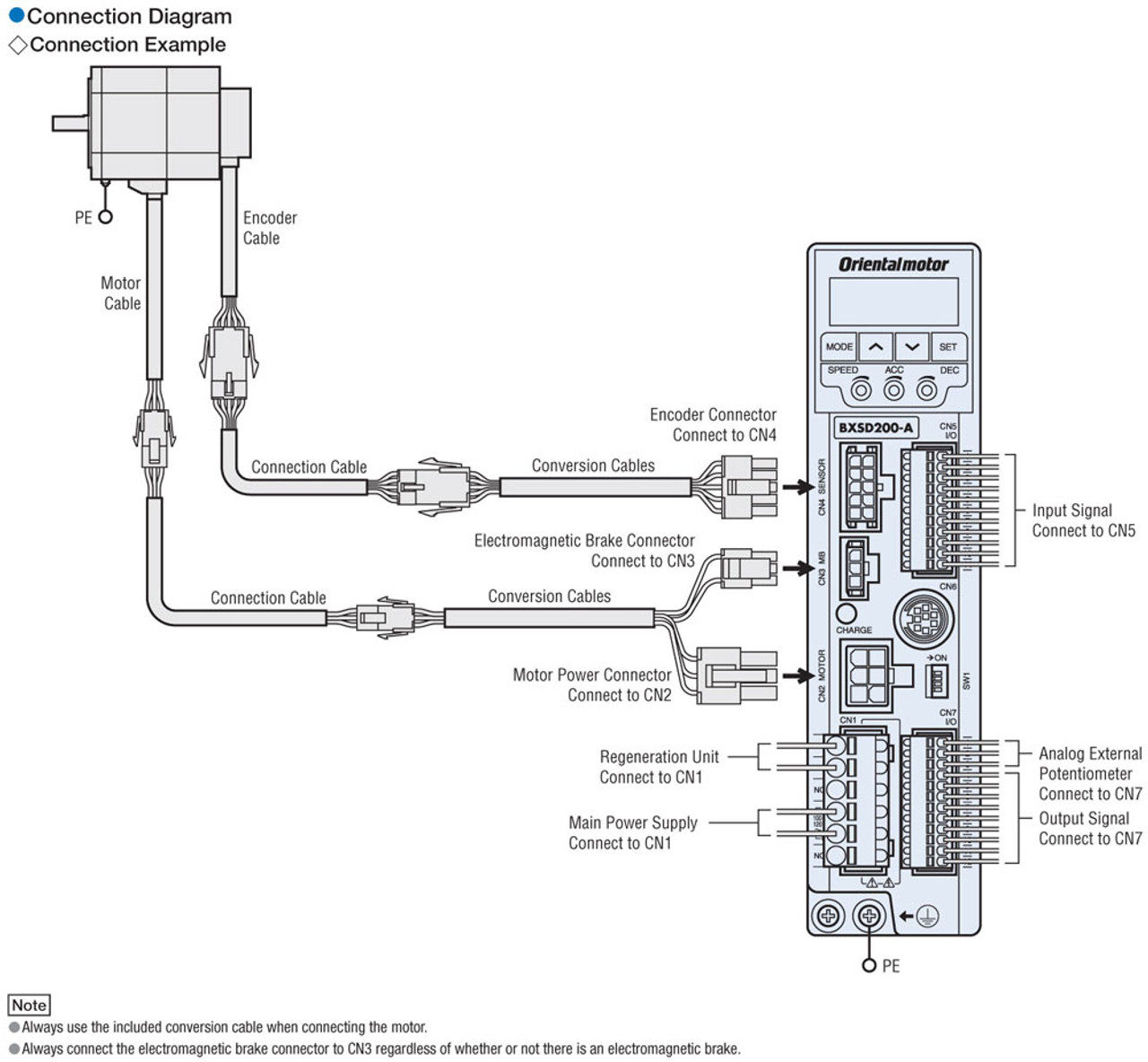

| Components | - GFS6G100FR [Gearhead], BXSD400-C [Driver], BXM6400M-GFS [Motor] |

| RoHS Compliant | - These products do not contain substances that exceed the regulation values in the RoHS Directive. |

| Safety Standards | - UL, CSA, CE |

| CE Marking | - Low Voltage Directives, EMC Directives |

| Insulation Resistance (Motor) | - 100 MΩ or more when 500 VDC megger is applied between the windings and the case after continuous operation under normal ambient temperature and humidity (except for encoder). |

| Insulation Resistance (Driver) | - 100 M Ω or more when 500 VDC megger is applied between the power supply input terminal and the case, and between the power supply input terminal and the I/O terminal after continuous operation under normal ambient temperature and humidity. |

| Dielectric Strength (Motor) | - Sufficient to withstand 1.5 kVAC at 50 Hz applied between the windings and the case for 1 minute after continuous operation under normal ambient temperature and humidity (except for encoder). |

| Dielectric Strength (Driver) | - Sufficient to withstand 1.5 kVAC, 50 Hz applied between case and power supply input for 1 min. and 1.5 kVAC, 50 Hz applied between power supply input and the I/O terminal for 1 min. after continuous operation under normal ambient temperature and humidity. |

| Temperature Rise (Motor) | - Temperature rise of the windings is 50ºC (90ºF) max. and that of the case surface is 40ºC (72ºF) max, measured by the thermocouple method after rated continuous operation under normal ambient temperature and humidity. |

| Temperature Rise (Driver) | - Temperature rise of the heat sink is 50ºC (90ºF) max. measured by the thermocouple method after rated continuous operation under normal ambient temperature and humidity. [60ºC (108ºF) max. when drivers are installed in contact with each |

| Ambient Temperature Range | - [Motor] 32ºF ~ 122ºF (0ºC ~ 50ºC), nonfreezing [Driver] 32ºF ~ 72ºF (0ºC ~ 40ºC) when drivers are installed in contact with each other |

| Ambient Humidity | - 85% max. (non-condensing) |

| Operating Atmosphere | - No corrosive gases or dust. Cannot be used in a radioactive area, magnetic field, vacuum, or other special environments. |

| Altitude | - Max of 10000 ft. (3000 m) above sea level |

| Insulation Class | - UL/CSA Standards: 105 (A), EN Standards: 120 (E) |

| Degree of Protection | - IP54 (excluding connectors) [Motor] IP20 [Driver] |

Product options for BXS6400CM-100FR

Product tips for BXS6400CM-100FR

Product announcements for BXS6400CM-100FR

Product documents for BXS6400CM-100FR

| - Product Catalog | |

| - BX II Series User Manual | |

| - OPX-2A Operating Manual | |

| - 3D CAD (Motor) (*.step) | |

| - 3D CAD (Driver) (*.step) |