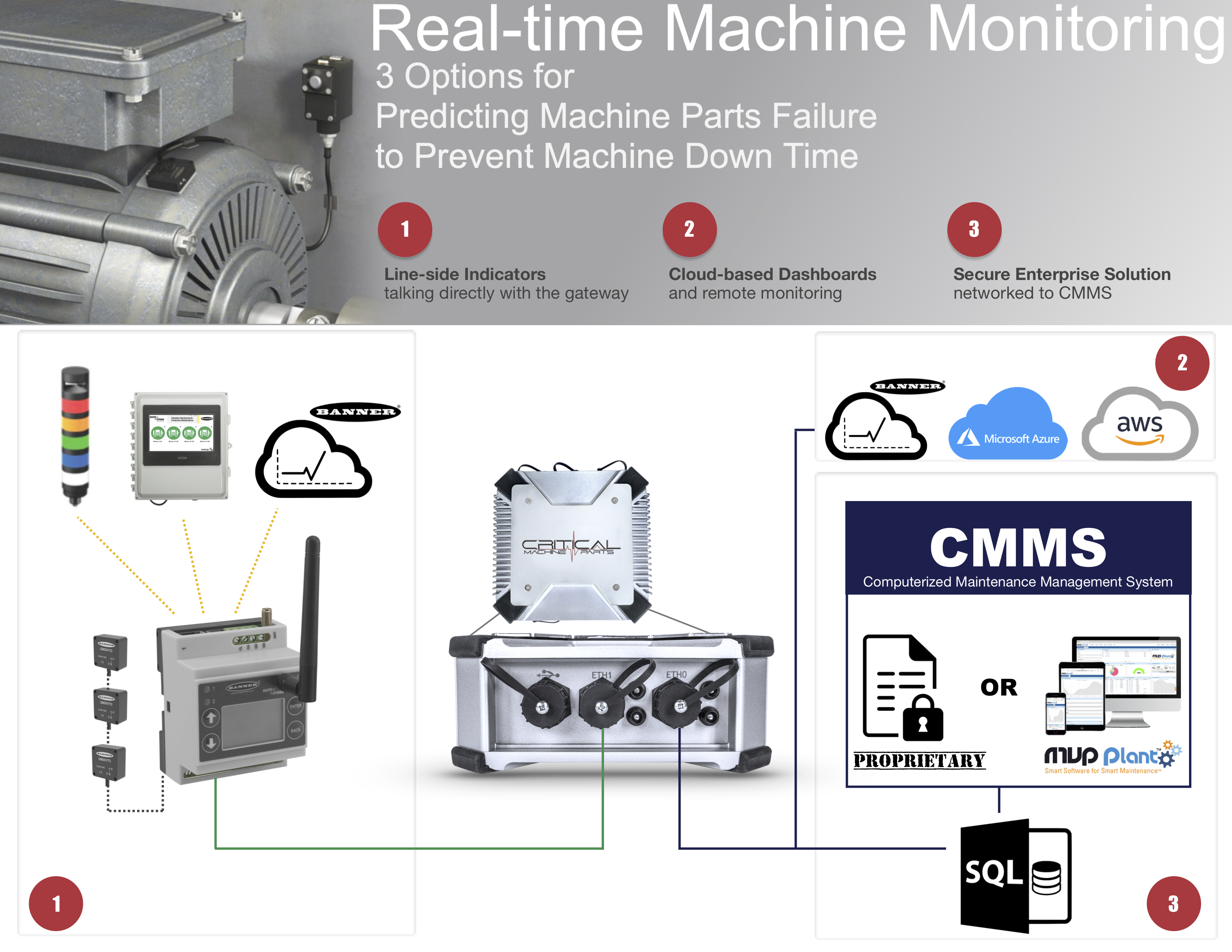

Predictive Maintenance

Predictive Maintenance Out-of-the-box

Our CMMS Appliance is pre-programmed to create work orders triggered by vibration and temperature alarms. Thresholds are automatically set by the sensor gateway measuring each component's normal operating conditions over time. When the vibration or temperature thresholds are breached, the gateway's alarm is translated by the CMMS Appliance to create a work order in maintenance's CMMS software with all of the recorded sensor conditions.

Easy-to-Configure Machine Monitoring

Choose any or all configuration options:

1. Line-side indicators

2. Cloud-based remote monitoring

3. Secure, on-premise CMMS

Enter IP addresses and CMMS fields:

Preconfigured with the monitoring sensors and CMMS software. Simply give everything an IP address to communicate.

Catch and replace machine parts before they fail:

Every component with a sensor talks natively to databases to avoid surprise failures and improve profit-centered maintenance operations.

Simplify Predictive Maintenance with a CMMS Appliance Kit.

Connect CMMS to vibration and temperature sensors to replace critical parts before failure.

Industrial network security designed into a hardened appliance.

Built-in integration of device drivers for industrial control systems and database connectors.